Planking

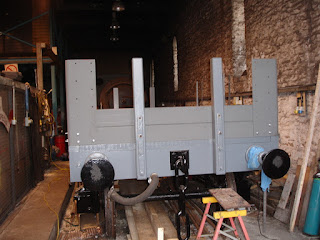

Today saw some more significant progress of work on the wagon.

The planks for the ends and sides were painted with undercoat when I arrived at Bitton today and I began cutting the chamfers at to accommodate the curve of the corner plates on the ends of the end planks.

When Ollie arrived we began putting on the first row of end and side planks.

Timber is living stuff, even when it's cut into planks. What were straight planks when they were cut have dried and twisted enough to make fitting them a slow and careful process. We began with one of the end planks, putting it in place and clamping it to the headstock and to the end supports before drilling the two holes for the bolts into the end supports. It was a slightly nervous procedure because the plank was twisted enough to show, but as we tightened the bolt the twist was pulled straight and the plank lay along the edge of the floor.

Next we put in the first side plank, which we clamped down to the sole bar. Then I went into the wagon and Ollie lifted the corner plate into position. They are heavy and I had quickly to clamp it to the end and side planks. Then we adjusted the position of the plate so that it sat level with the bottom of the planks and perpendicular.

When we were satisfied that it was positioned right and square we drilled through and bolted it to the end plank. Then we checked again that the side plank was firmly in place and the corner plate still square to it before drilling and bolting through the corner plate and into the side plank. Lastly we drilled through the holes in the J irons into the end of the side plank by the door opening and bolted it into place there.

We did that four times. Once for each corner.

Now the wagon is ready to receive the rest of the planks, but we ran out of time today and that will have to wait until next week.

Today saw some more significant progress of work on the wagon.

The planks for the ends and sides were painted with undercoat when I arrived at Bitton today and I began cutting the chamfers at to accommodate the curve of the corner plates on the ends of the end planks.

When Ollie arrived we began putting on the first row of end and side planks.

Timber is living stuff, even when it's cut into planks. What were straight planks when they were cut have dried and twisted enough to make fitting them a slow and careful process. We began with one of the end planks, putting it in place and clamping it to the headstock and to the end supports before drilling the two holes for the bolts into the end supports. It was a slightly nervous procedure because the plank was twisted enough to show, but as we tightened the bolt the twist was pulled straight and the plank lay along the edge of the floor.

Next we put in the first side plank, which we clamped down to the sole bar. Then I went into the wagon and Ollie lifted the corner plate into position. They are heavy and I had quickly to clamp it to the end and side planks. Then we adjusted the position of the plate so that it sat level with the bottom of the planks and perpendicular.

When we were satisfied that it was positioned right and square we drilled through and bolted it to the end plank. Then we checked again that the side plank was firmly in place and the corner plate still square to it before drilling and bolting through the corner plate and into the side plank. Lastly we drilled through the holes in the J irons into the end of the side plank by the door opening and bolted it into place there.

We did that four times. Once for each corner.

Now the wagon is ready to receive the rest of the planks, but we ran out of time today and that will have to wait until next week.

2 Comments:

Looking very nice :-)

I'm not entirely sure that the real MR would have taken so much care in waiting for the timber to settle. I have a feeling that they would have just bolted it in place and let nature do its worst!

Do you think that the wagon will be running in time for Christmas?

Flymo

I've had that conversation, Flymo. I suspect that working wagons like this were probably thrown together. However, it is not simply a working wagon any more, it's a preserved bit of railway history. I doubt there are many rebuilt all timber wagons around. I've seen one rebuilt and two in need of rebuilding. I wish I could have bought them but it would be way beyond my means.

This wagon is about 120 years old and all those years ago the builders would have had at their disposal well seasoned timber for both frames and planking. All we've got is kiln-dried stuff at best, and it twists.

Post a Comment

Subscribe to Post Comments [Atom]

<< Home